Setting Up and Adjustments

The separator requires an oil flow of 30 litres to 45 litres

per minute with a pressure between 150 and 205 bar.

On tractors with a high output oil flow exceeding 45

litres per minute the oil flow should be regulated to deliver

between 30 to 45 litres maximum.

Oil flow above this limit will result in

exceedingly high oil temperatures with the

possibility of damage to the separator

hydraulic system.

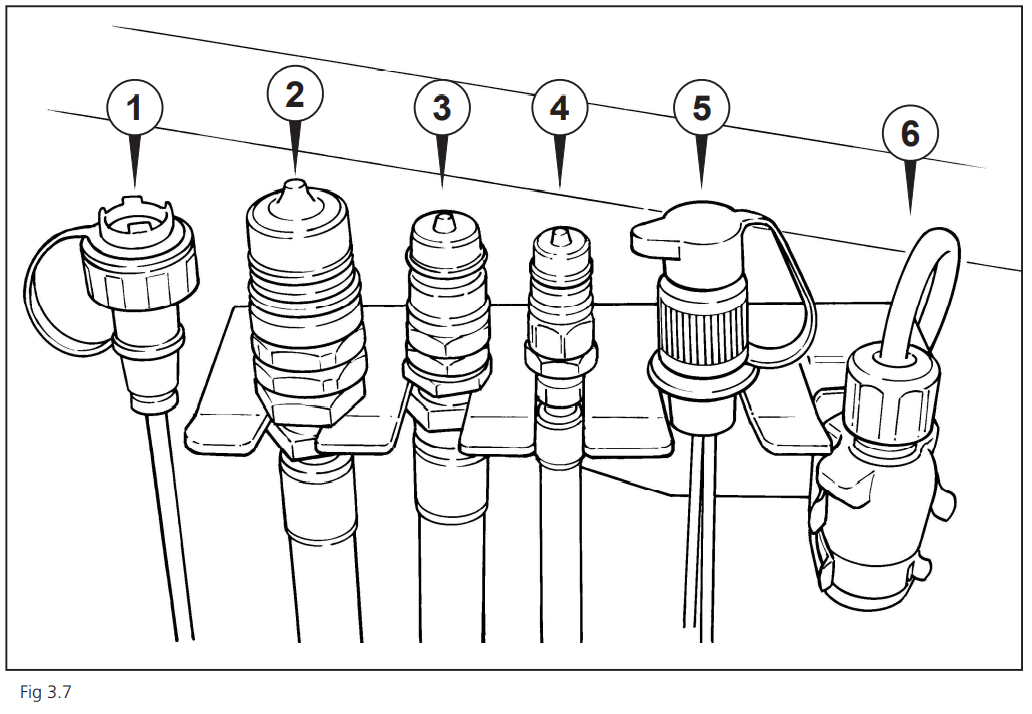

All hoses and connectors to be fitted to the tractor are

shown in Fig. 3.7.

1. Multi-pin Control Box plug.

2. BLUE banded RETURN hose.

3. RED banded PRESSURE hose.

4. Load sensing hose.

5. Live lead to Tractor

6. Road Light plug.

Hoses and plugs should be connected to the tractor as

follows:-

- RED banded hose to be connected to the tractor

PRESSURE spool outlet.

- BLUE banded hose to be connected to the tractor

RETURN spool inlet.

WARNING!

When connecting Pressure and Return hoses to the

tractor spool valves - take care to ensure Red banded

hose is fitted to the tractor Pressure outlet and Blue to

the Return inlet.

Connection in any other way will result in damage to the

separator hydraulic system.

- *Load Sensing hose to be connected to the tractor

load sensing coupler.

*(Read the section on ‘Load Sensing System’ page

3.4 for further instructions prior to starting up the

machine.

- Road light plug to be connected to the tractor auxiliary

socket.

- Multi-pin plug to be connected into the separator

control box.

- Live lead to tractor to be connected into the tractor

eurosocket or battery lead extension (supplied).

Note: A plug holder is provided at the front of the

machine (Fig 3.7.6) for storing the multi-pin control box

and road light plugs when not in use. Slots are also

provided for storing feed and return and load sensing

hose ends